Likes

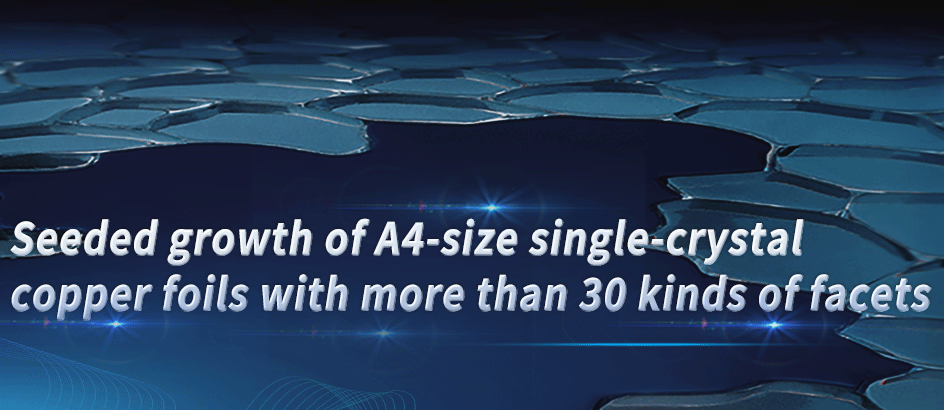

Prof. Xiaozhi Xu, a researcher from South China Normal University and the collaborators from Peking University, South University of Science and Technology of China and Korea Ulsan Science and Technology Institute have published their latest discovery entitled "Seeded growth of large single-crystal copper foils with high-index facets” on Nature. In the paper, the fabrication of A4-size single-crystal copper foil library by thermodynamic "abnormal grain seeding" control and kinetic "abnormal grain growth" control has been reported for the first time, and more than 30 kinds of single-crystal copper foils have been obtained.

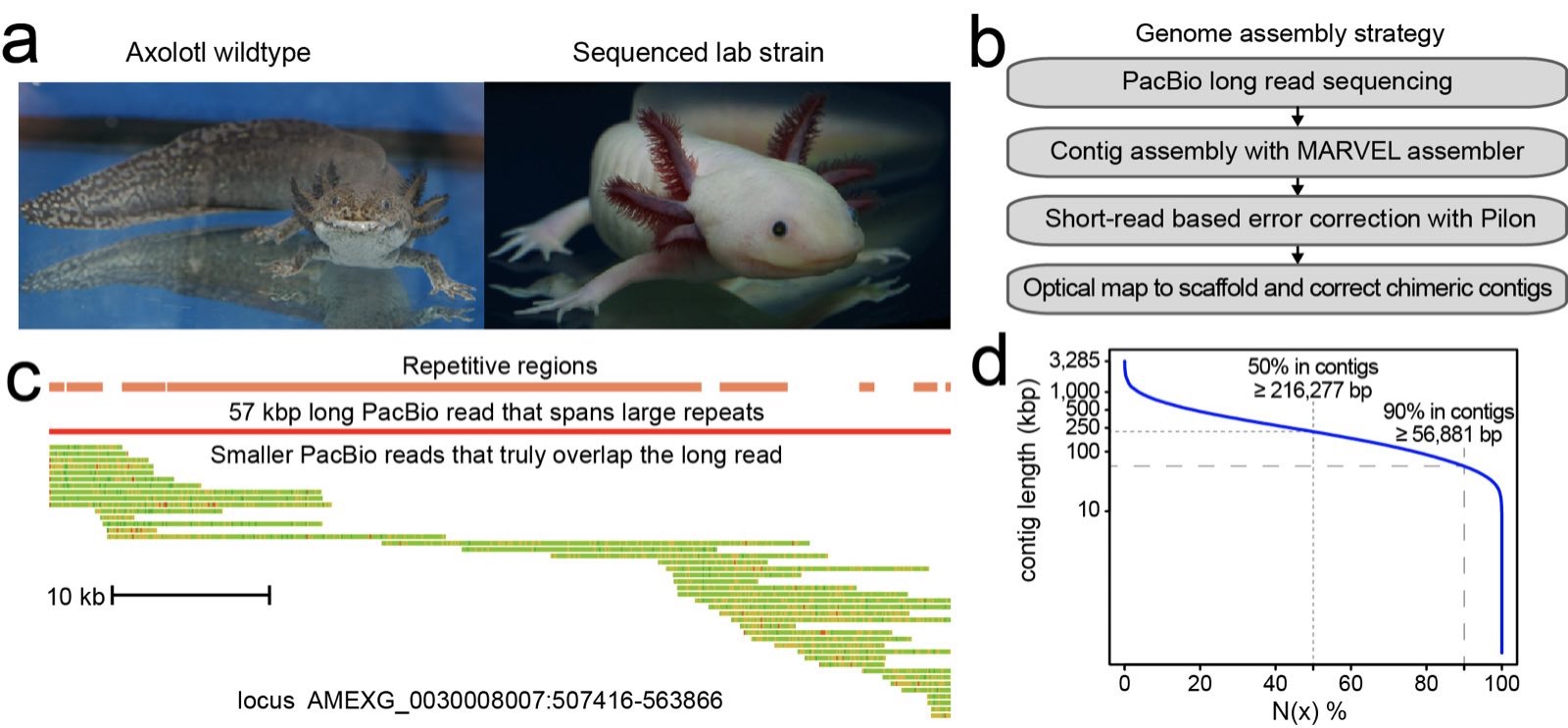

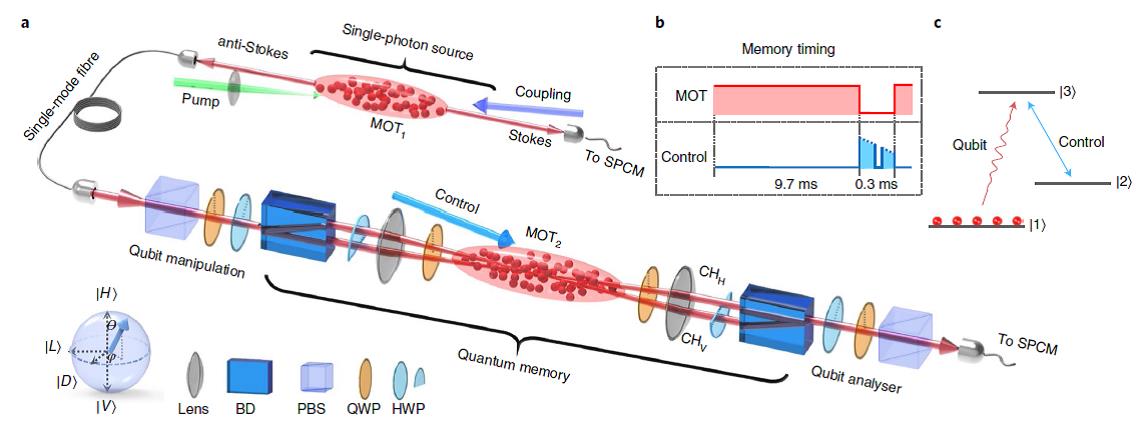

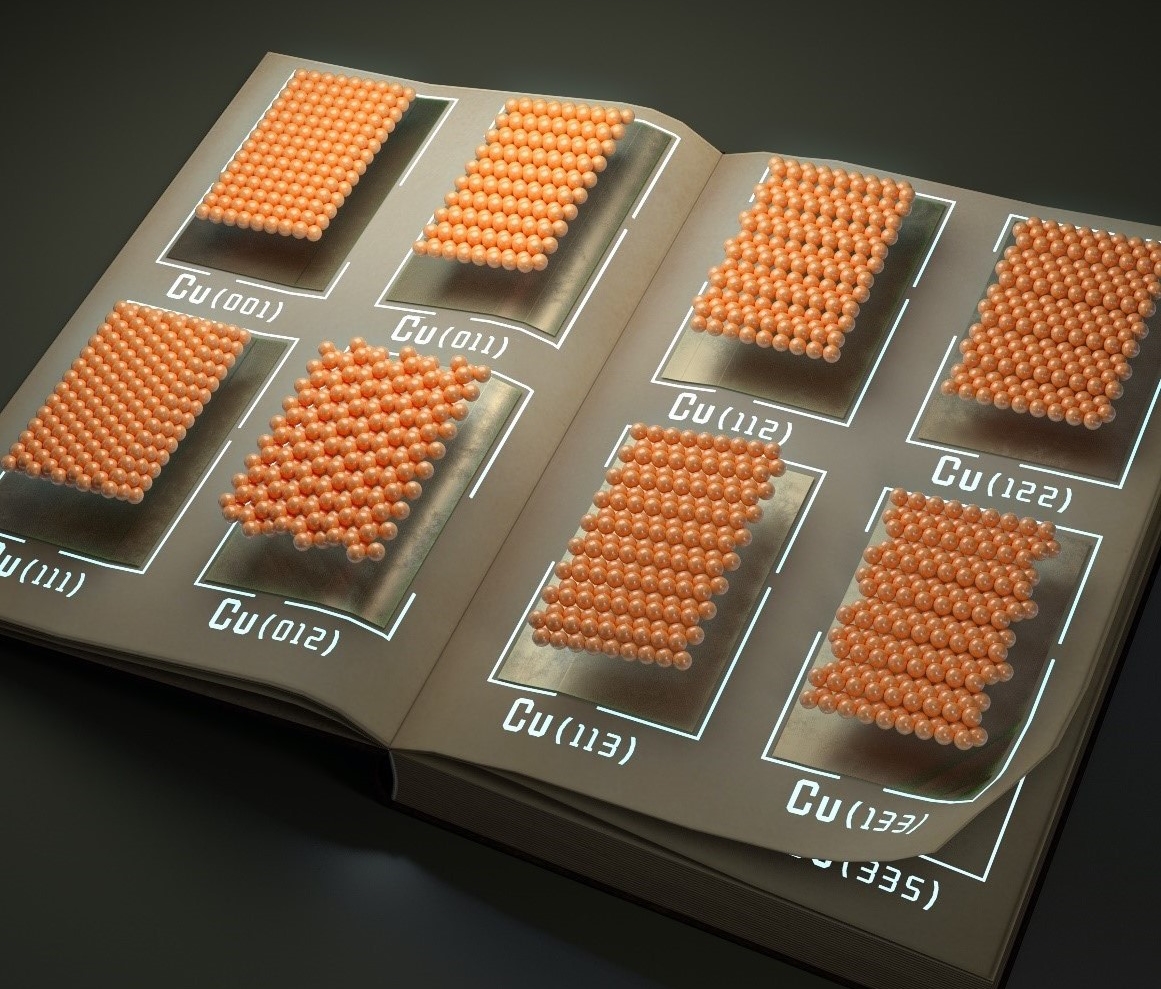

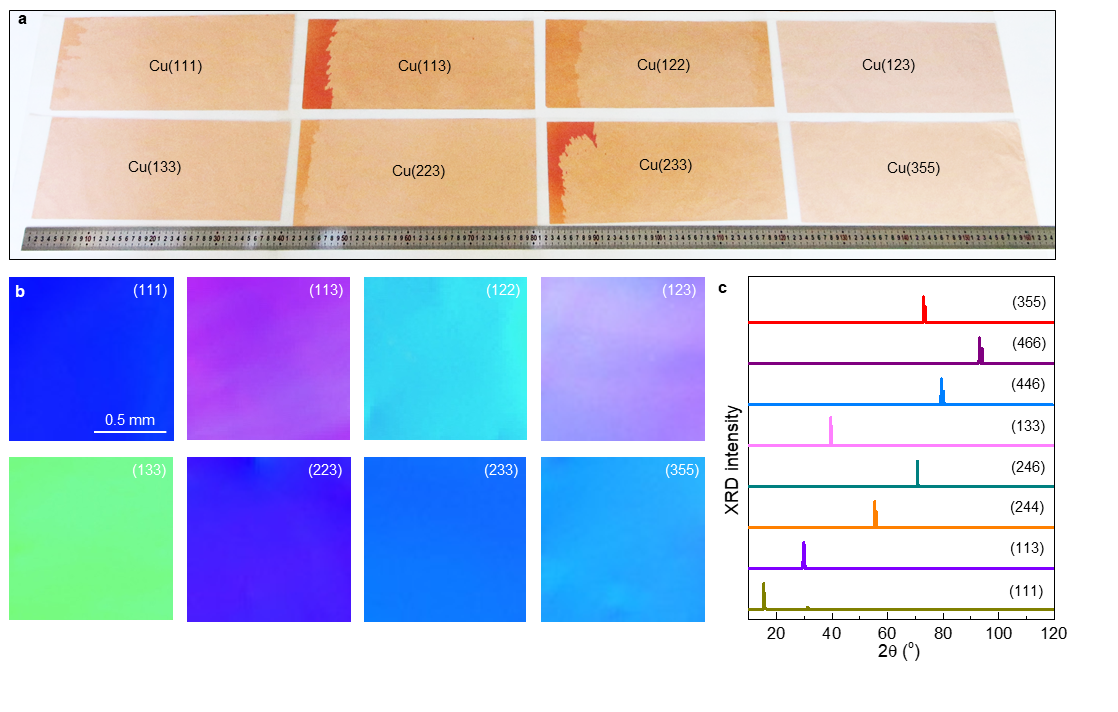

Schematic diagrams of large single-crystal copper foils with high-index facets

Copper was one of the earliest metals came into human’s history. The use of copper had a profound impact on the progress of human civilization. In today's society, copper, as a non-ferrous metal, has an extremely close relationship with human beings, which has been widely used in electrical, light industry, machine manufacturing, construction industry, national defense industry and other fields. Single-crystal copper foil has no grain boundaries, fewer defects, and smaller direct current resistance, so it has better conductivity, better anti-corrosion performance, and higher flexibility. Especially, in the current rapid development of 5G technology, single-crystal copper foil with better electrical, thermal, mechanical and anti-corrosive properties has great application prospects in electronic information field. Therefore, the preparation of large-size single-crystal copper foil is a long-term pursuit of the industrialists and scientists.

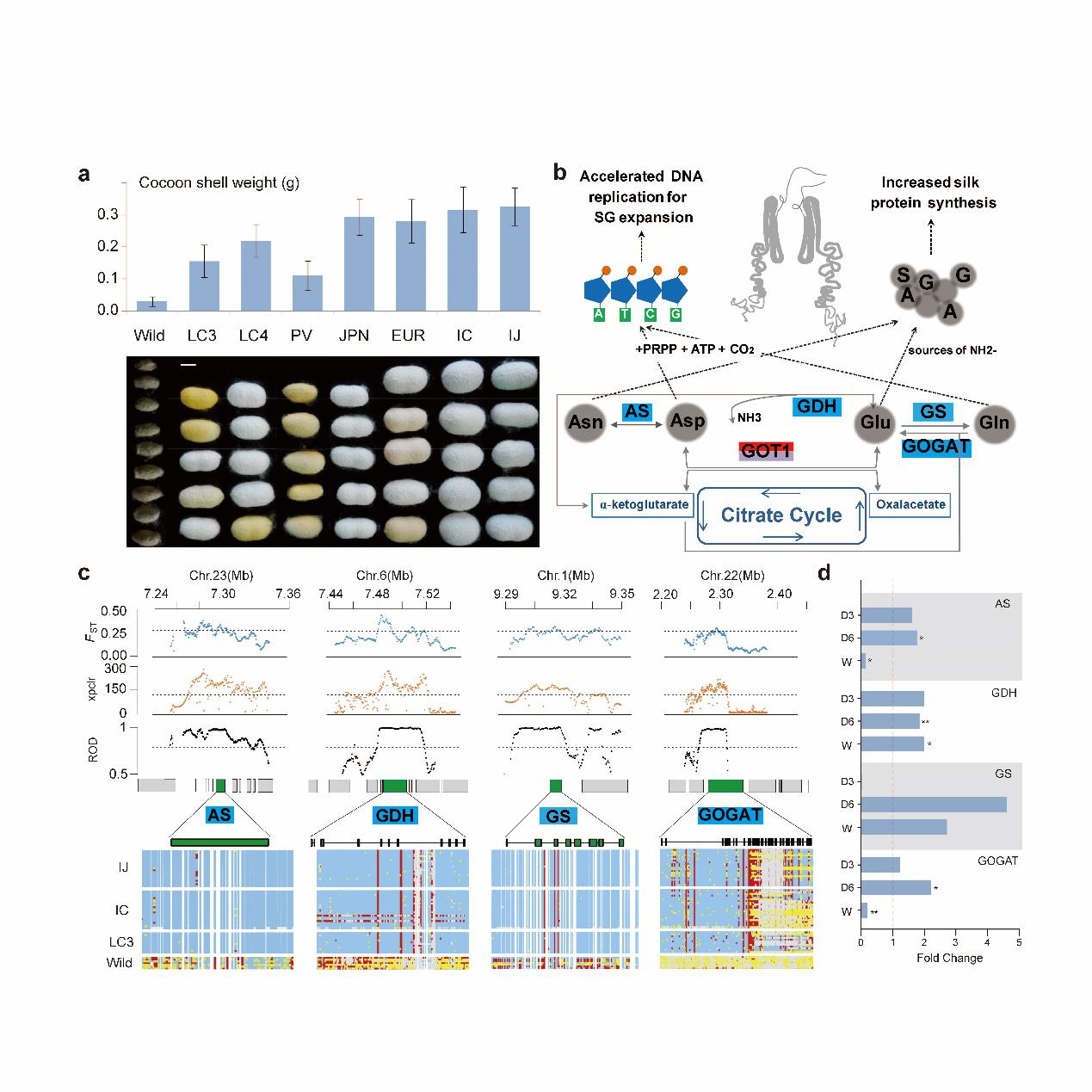

Based on their Miller indices {hkl}, metal facets can be classified into two types: low-index facets (only Cu (100), Cu (110), Cu (111)) and high-index facets (they are in principle infinite). High-index copper facets could afford richer surface structures and properties, thus is an ideal substrate for epitaxial growth of 2D single-crystal materials with various symmetries. However, the controllable preparation of high-index single-crystal foils is challenging, as they are neither thermodynamically nor kinetically favourable compared to low-index facets. Currently, high-index metal foils are mainly obtained by cutting bulk single-crystal metal ingots, thus, only a few index choices are available, and the cost is very high. Additionally, in the typical cutting and polishing method, accurate index control and flat surfaces with uniformly parallel step edges are very challenging to realize. Therefore, the accurate production of large single-crystal metal foils with various high-index facets are in great demand.

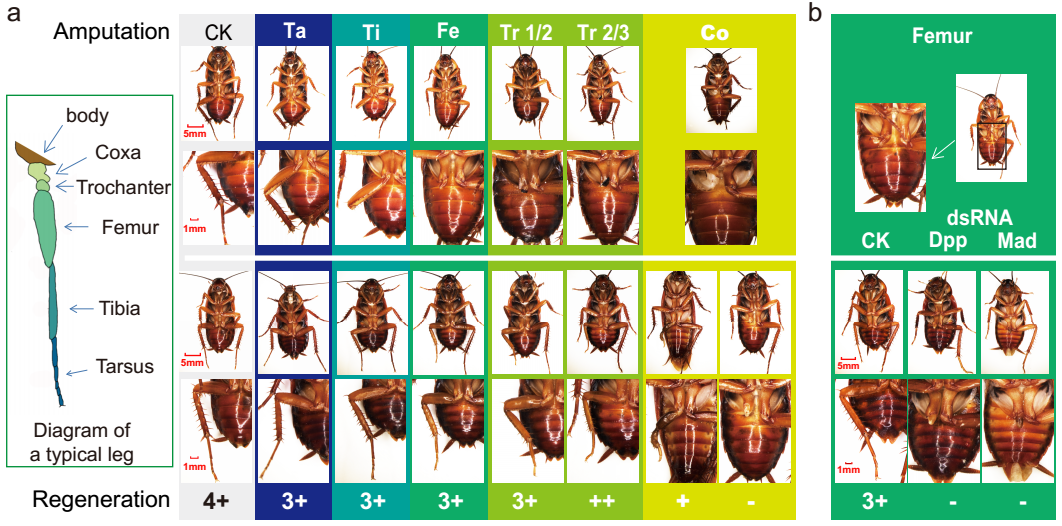

Figure. Two growth stage of abnormal grains and optical images and characterizations of the single-crystal Cu foils.

To address this problem, researchers have focused their research on thermodynamics and kinetics control of the recrystallization process. By applying the special pretreatment process, the Cu(111) facet is no longer the only thermodynamically favourable facet, and the abnormal high-index crystal nuclei are obtained. Kinetically, the large abnormal grain consumes the surrounding small normal grains and eliminates the grain boundaries in the Cu foil which leading to the formation of the large single-crystal copper foil. By repeating the procedure, more than 30 kinds of single-crystal Cu foils with various facets have been prepared. What’s more, in analogy with the "inheritance" in biology, researchers further proposed a facet ‘transfer’ method to copy the facet of the obtained high-index single crystals. First, a small piece of a high-index single-crystal Cu cut from a large single-crystal Cu foil was placed on a large polycrystalline Cu foil to serve as a new seed. When annealed at a high temperature, the polycrystalline Cu foil transferred into a single-crystal one with the same index as the seed. This method is universal and can be applied to the atomic manufacturing of other metals. The fundamental exploration and technical applications of these large high-index single-crystal metal foils are therefore ready and awaiting.

Xiaozhi Xu from School of Physics and Telecommunications Engineering is the co-first author of the paper. The research is supported by The Key R&D Program of Guangdong Province (2020B010189001), Guangdong Provincial Science Fund for Distinguished Young Scholars (2020B1515020043).

Paper link: https://www.nature.com/articles/s41586-020-2298-5

Source from the School of Physics and Telecommunication Engineering

Cover photo by Lv Wensi, Zhou Ruizhi

What to read next: